Changes are coming in established driver interface protocols

September 24, 2015

Many of the well-established protocols such as I2C, SPI, and USB are evolving. For example: I2C: Currently deployed at clock rates of 100 kHz and 400...

Many of the well-established protocols such as I2C, SPI, and USB are evolving. For example:

- I2C: Currently deployed at clock rates of 100 kHz and 400 kHz and up to 1 MHz, has now established 3.4 MHz and 5.0 MHz as newly supported clock rates.

- SPI: Typically used at clock rates below 33 MHz in a single I/O mode is now routinely exercised to clock rates ranging from 50 MHz to 80 MHz and above, with dual and quad mode I/O to further enhance programming speed/throughput.

- USB: Within a span of less than two years, the USB-IF has introduced clock rates to 10 Gbps, power delivery, and the new Type-C connector.

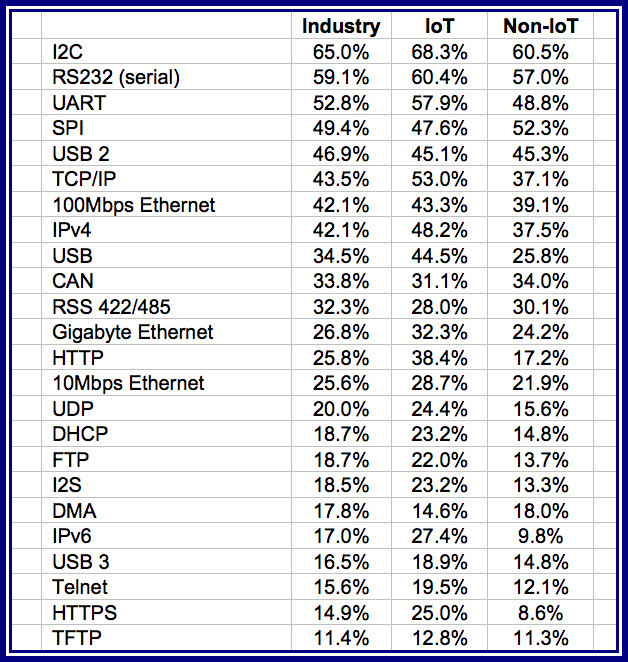

The data displayed in Table 1 is taken from the 2015 EMF Survey of Embedded Developers in response to the question “Which of the following products do you use in your embedded designs as a driver interface (both physical interfaces and network protocols)?” This question had 1,334 responses.

Table 1. Products used in embedded designs as a driver interface. (Click to enlarge)

Table 2 presents the frequency of use of each protocol in embedded developments. The data is broken into three cadres: total industry, IoT developments, and non-IoT developments. Since IoT is currently being pursued as a primary growth application, I’ve included the data for comparison. Of particular note is the prevalence of I2C, SPI, and USB among industry and IoT users.

Table 2. Frequency of use of each protocol in embedded developments.

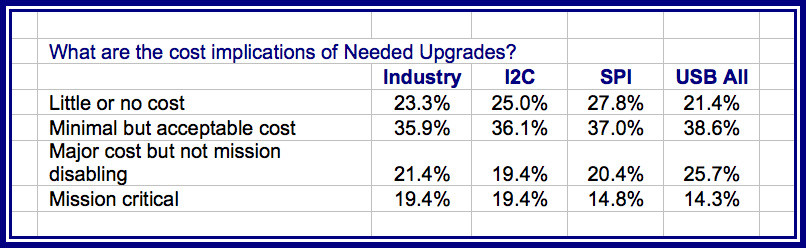

Let’s look at how often developments that use I2C, SPI, or USB are likely to be upgraded in the field as well as how costly such upgrades will be.

Table 3. Cost implications of embedded development tools.

Year over year, findings of the Embedded Market Forecast survey data indicate that the adoption of enhancements is increasing. This upswing and push for new capabilities creates a budgetary dilemma for many embedded engineers. Almost 75 percent of respondents indicate that there are cost implications associated with required upgrades, while about 40 percent categorize the cost implications as major or mission critical. Buying a new tool, capable of performing at the highest clock rates, lowest voltages, etc., is expensive. Purchasing a tool that can achieve the performance required for the task at hand but not meet the latest high performance specification, or known future potential, tends to result in premature tool obsolescence as new projects push the performance envelope.

Traditional scope vendors like Tektronix, Agilent/Keysight, etc., have solved this problem by providing “model series” (for example, 70 MHz to 200 MHz scopes, 100 MHz to 1 GHz scopes), each with options (like new protocol probes and decoding options) that can be added as customers’ requirements evolve. The challenge is that entry-level oscilloscopes within a series still tend to be expensive, option prices are often exorbitant, and the series itself defines the upper performance band. It just isn’t economically feasible to future proof with these larger tools.

Some smaller toolmakers, like Total Phase, have finally have solved the dilemma. Their latest generation of tools is no longer task specific (e.g., program SPI at up to 8 MHz, sniff SPI at up to 24 MHz, etc.), but consists of complex FPGA-based platforms with customization capabilities beyond their predecessors. The result is the access to relevant technology in cost-effective tools that was previously unattainable in earlier generations. The added benefit of this platform approach is that specific advanced platform capabilities now span the entire platform into all applications. Items like integrated voltage-level shifting and Ethernet connectivity are “table stakes” for high-end tools; but were never available in lower cost tools, until now. By using one highly configurable platform, you can cost effectively receive those desirable cross-platform capabilities in a lower cost tool, while only purchasing the application for the performance you need, when you need it.

An engineer can still opt for lower cost versions of the newest tools (fully loaded with applications to meet today’s needs, just not configured for the all future permutations) all the way through to fully loaded devices. The difference is that the new platform architecture lets end-users purchase high-performance applications only when they need them. This effectively eliminates the need for “overbuying” up front, or risking premature obsolescence by selecting the previous generation tools.

Budget and performance always determine the best value for tool selection for an embedded project, but for the first time, you can get exactly what you need, when you need it, meaning high-performance capability without breaking the bank. And when your next project comes along with even more challenging requirements, you can install applications to meet those increased needs, at a cost far lower than completely replacing outdated tools.

Jerry Krasner, Ph.D., MBA is Vice President of Embedded Market Forecasters and its parent company, American Technology International. A recognized authority with over 30 years of embedded industry experience, Dr. Krasner has extensive clinical research and medical industrial experience, including the successful filing of over twenty 510k submissions. He earned BSEE and MSEE degrees from Washington University, a Ph.D. in Medical Physiology/Biophysics from Boston University and an MBA from Nichols College. He has been a visiting professor at the Universidad de Las Palmas (Spain) where he was recognized for his work in neurosciences and computer technology.